There are many buzzwords floating around in the world of metrology. When it comes to determining what you would ultimately like to do with your data, it is key to understand the difference between sparse and dense data.

The defining differences between these two types of data are how many data points are collected and the techniques used for collection. Typically, in dense data collection, non-contact scanning devices gather large volumes of data points en masse, creating large meshes or patches which describe the surfaces of everything being scanned. The deliverable in this case is a set of data points called a point cloud, comprised of a potentially massive volume of information. Since there is such a large quantity of information to sort through, the user must reduce that information in some way to make it useful. This might be done via cloud processing or algorithmic decimation, but it requires extra work and effort.

Sparse data, on the other hand, is much lower in volume. In general, this form of data is most often collected one or a few points at a time using a non-scanning contact tool such as a digitizing probe, or traditional measurement tools such as a set of calipers or pin gauges. Since sparse data is generally collected point-by-point, the user must decide which sets of points are most important in determining what the end product should be, which can bring into the work flow the element of design intent – the user’s vision of how the object should ultimately look and function.

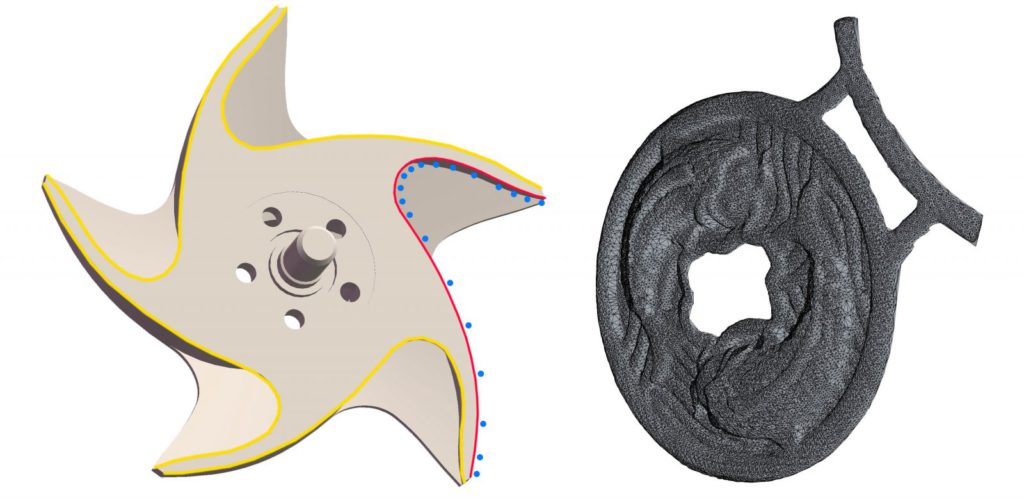

Sparse data and dense data clouds have many documentary applications, and depending on the use case, each can be a key asset for the user. For the purposes of reverse engineering, sparse data collection can be highly efficient. Representing direct-to-geometrical description, sparse data can be used to quickly turn a part or component into a 3D CAD model. Data collected with traditional hand tools may be difficult to translate directly into a 3D model but can easily be used to augment a sparse data collection process. Today’s sparse data digitizing tools allow quick, simple measurement and an easy translation of that information into a useful parametric model.

In addition, the information collected to create the form and system is exactly what the user needs – there is no parsing through excess data to find what is necessary. Those physical features are automatically turned into geometry, then acted on in the CAD system to loft, cut, and extrude to create the desired virtual model forms.

Design intent in sparse and dense data

Assessing design intent is critical when you are reverse-engineering or collecting data from a part because subject parts rarely are perfect reflections of the original design. Parts deviate from design in manufacturing, through wear in use, and being damaged. Measuring the actual dimensions and adjusting to the desired nominal value is a powerful advantage of sparse data collection techniques. Adding design intent back into the component in the CAD system is easy to do within the sparse data workflow. With the single-point data process, the user only needs to directly choose the data that represents the feature in best condition and work straight from that form. With dense data scanning, it can be much more difficult to separate the good from bad data. Often, the dense data build process must start with an extensive cleanup effort to remove artifacts and extraneous captured data. This can make it much more difficult and time-consuming to adjust for imperfections within such a massive cloud of information and require specialized expertise beyond traditional CAD training.

A significant consideration for choosing between the two data collection methods is the time the part is available for documentation. In a very general assessment, it is faster to capture prismatic measurements with sparse data digitizing and faster to capture complex organic surfaces using dense data scanners. However, circumstances can easily flip the decision. If your window of availability is restricted, dense data scanning may be your only option, even for simple prismatic parts. If your organic model must be converted into a parametric CAD form, and you have access to the part for as long as you need, sparse data capture tools may be the better choice.

Examples of data collection

For example, measurement days are a common occurrence on the arrival of a new car model. At these events, aftermarket parts manufacturers are presented a limited time to capture the shape data they need in order to produce matching accessories. In this situation it is imperative that the manufacturer be able to quickly create a digital twin of the features that represent mating surfaces for the add-on parts they want to develop. Creating and storing a large point cloud set as a reference can be accomplished very quickly with a scanner and has a special benefit in this case. Point clouds are also highly useful for copying and making minor changes, such as scaling, that do not require parametric changes.

Now, imagine a similar situation where the aftermarket manufacturer only needs to capture the mounting geometry where a new part is to be attached and they have unrestricted access to the vehicle. Sparse data tools and techniques allow for quick, direct parametric capture of the needed forms.

Ultimately, the intended use of the data is critical to the choice of method. Scanning, cleaning, filling holes, and 3D printing can be done relatively quickly with scanning tools and methods; however, making the jump to parametric modeling and the associated cleanup, modifying, and extracting of geometry is non-trivial and time-consuming to do with dense data. The reduction of a point cloud into a parametric form is a “slice and dice” process comparable to the construction process used in the sparse data collection method. This obscures the choice between methods when a parametric form is the desired result.

Specialties of sparse and dense data

The processes of using the tools for sparse and dense data collection require expertise and experience, which translate into specialties for each. The user must determine what kind of filters to use and how to parse through the data. When performing direct-contact digitizing of single-point sparse data, the person performing the data collection needs to know what they are collecting, how it will be used, and have a concept of how they plan to build the object inside of a CAD system or data collection environment. For dense data, the user might be a specialist in collecting raw masses of data without needing to know the design intent. This potential for the separation of specialties is a unique attribute of scan-based documentation.

Conclusively, there are several pros and cons for choosing a sparse vs. dense data collection process, and which tools you decide to employ. Sparse data collection methods may require prolonged part access, but you can more easily impart design intent during a direct build process, using your expertise to efficiently reshape imperfections or reimagine on the fly. Dense data collection methods provide an opportunity to quickly archive a mass of information and provide the opportunity to separate data collection and CAD model creation as distinct activities. You can clean up and remanufacture as-is or make the decision to execute a more involved parametric extraction from the data set. The additional time and effort required may be a necessity due to limited part availability or surface complexity, or simply desirable for the ability to delegate work.

Your choice of methods may be determined by part-time, tool availability, or simply personal preferences. This view into some primary characteristics defining sparse and dense data may help you when making your choices about how to equip yourself for digital documentation work to come. At the end of the day, the key is to collect data to create something useful.

Tom Welsh

President and CEO, Revware, Inc.

Copyright© 2021 Revware Inc. All rights reserved. Reuse and reprint allowed only with permission by Revware Inc., and with appropriate acknowledgements.

About Revware

Revware provides high, quality, simple to use, innovative, cost-effective modeling solutions to solve your design, metrology, and engineering problems.